Method for preventing electrochemical corrosion of detachable plate heat exchanger

In the detachable plate heat exchanger, the plates are mainly in contact with the upper and lower guide rods. The upper guide rods are generally H-shaped steel or I-beam steel, the material is carbon steel, and the plate materials are generally various grades of stainless steel. The plate and the upper guide The rods are in close contact. When stainless steel and carbon steel are in contact, the potential difference between stainless steel and carbon steel is obvious. The environment of the heat exchanger is generally a relatively humid or water environment, which forms an electrochemical primary battery. , An electrochemical reaction occurs between the two, and stainless steel produces intergranular corrosion. Normally, carbon steel corrodes in the environment.

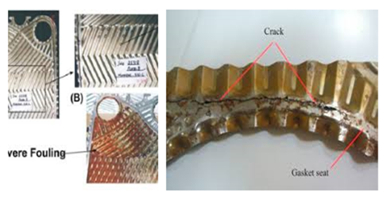

(The picture comes from the Internet, if there is any infringement, please contact us to delete)

However, if it is in the environment of chloride ions (such as seawater), the corrosion of carbon steel is very slight, and pitting corrosion of stainless steel will occur, because the oxide layer protective film on the surface of stainless steel is penetrating The strong chloride ion will soon be destroyed, and local galvanic corrosion will occur. The metal in the passive state still has a certain reaction ability, that is, the dissolution and repair (passivation) of the passive film is in a dynamic equilibrium state. When the medium contains active blocking ions (commonly known as chloride ions), the equilibrium is destroyed and dissolution predominates. The reason is that chloride ions can preferentially adsorb on the passivation film, squeeze out the oxygen ions, and then combine with the cations in the passivation film to form soluble chloride, resulting in small corrosion at specific points of the newly exposed base metal The pits (the pore diameter is mostly 20 ~ 30µm). These small pits are called hole erosion nuclei, which can be understood as the active center generated by the hole erosion. Will accelerate the corrosion of stainless steel.

Qingdao reapter adopts a new way to separate the upper guide rod made of carbon steel from the heat exchange plate made of stainless steel. The specific method is:

1. The upper guide bar is not in contact with the heat exchange plate, and cannot form an electrochemical reaction, delaying the corrosion of the heat exchange plate.

1. The upper guide bar is not in contact with the heat exchange plate, and cannot form an electrochemical reaction, delaying the corrosion of the heat exchange plate.

2. The guide rod part and the heat exchange plate change from point contact to line contact, and the positioning effect is better

Qingdao Reapter Heat Exchange Equipment Manufacturing Co., Ltd. is actively forging ahead, constantly updating its technology and upgrading its industry, and providing one-stop detachable plate heat exchanger equipment solutions.

Related information

- High-end plate heat exchanger supporting can also choose domestic, some concepts have to change

- The production process of plate heat exchanger plates is interpreted by the manufacturer!

- A quick introduction to the classification and application of plate heat exchanger gaskets

- In the beer brewing process, how can we use "Alfa Laval" plate heat exchangers with less money

- What is the production and processing technology of Qingdao Ruipute plate heat exchanger plate?

- How to improve the thermal efficiency of the plate heat exchanger?

Relevant article

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!