-

Double Wall Plates And Gaskets

The plate of the double wall plate heat exchanger replaces the single plate type with two welded plates. Once the plate is cracked or perforated, the fluid will flow between the two plates to the outside, which is easy to be found and taken. Doing this can avoid contamination or adverse reactions caused by the mixing of the two heat exchange media.More +

-

Plate And Shell Heat Exchanger Plate Pack

A bunch of circular plates made of stainless steel or other alloy material are laser welded into one body, called a heat exchanger lathed bundle, then placed in a cylinder to form a plate and shell heat exchanger. The plate and shell heat exchanger has the advantages of temperature resistance and pressure resistance with shell and tube heat exchanger, and also the advantages of high efficiency, compactness with plate heat exchanger.More +

-

Double wall plate heat exchanger principle

The double wall plate heat exchanger plate is welded integrally with two thin plate pieces along the corner hole of each pair of plates. When the plate leaks, for example, the perforation caused by long time working will be easily detected from outside. Thereby it stops mixing between two materials.And at the same time, they plays very important roles towards warning internal leakage. Combined with the double seal of the gasket, the possibility of mixing two materials is avoided, and it is suitable for applications with high sanitary requirements or high safety and reliability of industrial production. Since the two sheets are welded to form a sheet, the heat transfer coefficient is inevitably lowered, but the highest safety is achieved in preventing materials mixing.More +

-

Semi welded plate heat exchanger

The semi welded plate heat exchanger is composed of a pair of plates, and each of the two plates is laser welded to form a pair of plates. It is sandwiched between the fixed pressing plate and the movable pressing plate in a superimposed mannerMore +

-

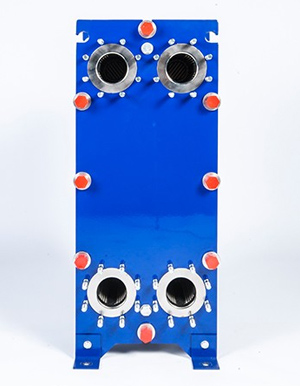

Plate heat exchanger

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that is assembled from a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between the various sheets, and heat is exchanged through the sheets.More +

-

Wide gap plate heat exchanger

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that is assembled from a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between the various sheets, and heat is exchanged through the sheets.More +

-

Food grade plate heat exchanger

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that is assembled from a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between the various sheets, and heat is exchanged through the sheets.More +

- [Latest news]Heat station supporting plate heat exchanger installation is a technical work, these points should be noted2021.12.10 08:41

- Heat station supporting plate heat exchanger production completed need to be transported to the heat station for installation, many people will think that the installation is a very simple thing, in fact, it is not, the installation is also a technical work, there are also some matters needing attention, today to introduce exactly what places need to pay attention to.

- read(34)

- [Latest news]Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what2021.12.10 08:37

- With the continuous development of the sulfuric acid production industry, the demand for industrial plate heat exchangers used in the production process is also increasing, so do you know what issues should be noted in the design of heat exchange equipment for sulfuric acid?

- read(49)

- [Latest news]Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency2021.12.09 01:20

- Coal chemical plate heat exchanger in the use of a period of time, are more or less will produce some accumulation of scale, these accumulations will not only cause corrosion of the equipment, but also affect the efficiency of work, so to timely cleaning, today introduced a simple and limited chemical cleaning method.

- read(11)

- [Latest news]A high-quality petrochemical plate heat exchanger in the production of what to consider2021.12.09 01:12

- Petrochemical products are closely related to our lives, from space ships, airplanes, cars on the ground, to our daily use of computers, desks, clothing, a variety of building materials, etc., all have a close relationship with petrochemicals. The petrochemical industry provides us with all kinds of daily necessities.

- read(18)

- [Latest news]These causes of chemical plate heat exchanger gasket aging you may not know2021.12.08 07:39

- The chemical plate heat exchanger gasket is an extremely critical component, and the requirements for the gasket are extremely high in strong corrosive media. When we use, we will find that the gasket aging. What is the cause of this?

- read(12)

- [Latest news]Chemical plant plate heat exchanger, sulfuric acid cooling needs attention2021.12.08 07:37

- Sulfuric acid is produced with cooling, so chemical plant plate heat exchangers are used in many applications. In the sulfuric acid purification process, power wave scrubbers, cooling towers, fiber mist eliminators and heat exchangers for sulfuric acid cooling are used.

- read(34)

- [Latest news]High-end plate heat exchanger customization, specifically for your special working conditions2021.12.07 01:24

- With the expansion of plate heat exchanger application industries and fields, there are more and more special media and special working conditions, ordinary plate heat exchangers can no longer meet the requirements of use, the demand for high-end plate heat exchanger customization is growing, what are the conditions to meet its requirements?

- read(6)

- [Latest news]The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth2021.12.07 01:18

- The boom in all industries requires a wide variety of gasketed industrial plate heat exchangers, and it can be used in virtually all types of industries. Its versatility allows it to be designed and configured for a wide range of applications, from relatively simple, low-demand conditions to very demanding performance requirements. It is primarily used for heating, cooling, heat recovery, condensation and evaporation.

- read(2)

- [Latest news]Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled2021.12.06 03:01

- About its price we usually know is related to its working conditions, but there are many people will wonder why the same working conditions, industrial plate heat exchanger wholesale prices are different? Today to introduce the price difference in the end is what factors lead to.

- read(5)

- [Latest news]The original lubricant in the chemical plate heat exchanger plays so many roles!2021.12.06 02:56

- We all know that the chemical plate heat exchanger its status in the chemical production is widely used. Equipment for a long time to use the machine internal and external cleaning, maintenance, in the maintenance process is the need to use to the lubricant, then I will give you an introduction to the lubricant in the chemical plate heat exchanger can play what role?

- read(3)

- [Latest news]Chemical plate heat exchanger, plate corrosion causes a brief analysis2021.12.03 06:34

- Plate heat exchanger for chemical industry has been dominating the heat exchange market in the chemical industry and is widely used. With this, there are also some problems, today we will talk about the plate heat exchanger plate in what circumstances will appear the phenomenon of corrosion.

- read(2)

- [Latest news]Do you know what kind of strength to have to be called a plate heat exchanger manufacturing plant?2021.12.03 06:25

- With the development of plate heat exchanger technology and materials technology, its application range and industry is becoming more and more extensive, the market demand for plate heat exchangers is very large, the market is flooded with a large number of claims of plate heat exchanger manufacturing plant, with what kind of strength to be called so?

- read(2)

- [Latest news]Heat exchanger station supporting plate heat exchanger or have to pay attention to these points, or easily go wrong2021.12.02 03:26

- Heat exchanger station supporting plate heat exchanger is the main equipment for heat exchange in the heat exchanger station, which together with the circulation pump, decontaminer, charge pump, control valve, metering table, etc. form a complete set of heat exchange system to provide assistance for central heating, bringing warmth to thousands of households.

- read(1)

Related search

Hot spot focusing

- 1Shandong Hengbang uses Ripute semi-welded evaporator and condenser case

- 2Haier new materials use Ripute small plate heat exchanger case

- 3Chuanqing Drilling Engineering Company uses Repute plate and shell heat exchanger case

- 4As a manufacturer of Plates and Gaskets, what are the advantages of Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd ?

- 5As a manufacturer of plate heat exchangers, what are the advantages of Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd?

- 6What are the advantages of plate heat exchangers compared to conventional heat exchangers?