-

Double wall plate heat exchanger principle

The double wall plate heat exchanger plate is welded integrally with two thin plate pieces along the corner hole of each pair of plates. When the plate leaks, for example, the perforation caused by long time working will be easily detected from outside. Thereby it stops mixing between two materials.And at the same time, they plays very important roles towards warning internal leakage. Combined with the double seal of the gasket, the possibility of mixing two materials is avoided, and it is suitable for applications with high sanitary requirements or high safety and reliability of industrial production. Since the two sheets are welded to form a sheet, the heat transfer coefficient is inevitably lowered, but the highest safety is achieved in preventing materials mixing.More +

-

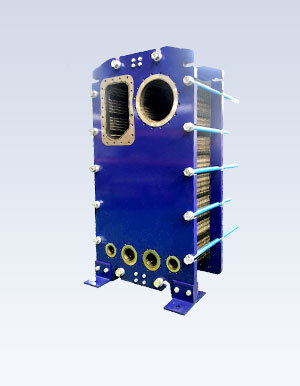

Semi welded plate condenser

The plate condenser consists of plates that are welded together in pairs to form a so-called plate set. The concept of a plate set leads to two different types of channels: a weld channel for condensing steam and a gasket seal channel for cooling water. This type of plate is specially designed for optimum condensation. It has an asymmetrical arrangement with a large gap on the steam side and a small gap on the cooling water side. This makes it possible to maintain a very low pressure drop at the steam end while maintaining a certain speed and turbulence on the cooling water side. This maximizes heat transfer efficiency and minimizes fouling.More +

-

Semi welded plate evaporator

Qingdao Ruipute plate evaporator is welded with a special corrugated pair of plates to produce high intensity turbulence, which greatly improves the heat transfer coefficient. The increase in heat transfer efficiency means a reduction in the required heat exchange area, which greatly saves investment costs, especially when special materials are required. The plate evaporator is compact and economical, so it replaces the conventional bulky and costly falling film equipment. The plate evaporator has a wide plate gap, a wide channel opening and laser welding that ensuring the vacuum low pressure evaporation process to be performed in both aqueous and organic systems.More +

-

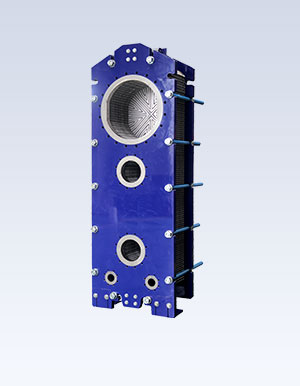

Semi welded plate heat exchanger

The semi welded plate heat exchanger is composed of a pair of plates, and each of the two plates is laser welded to form a pair of plates. It is sandwiched between the fixed pressing plate and the movable pressing plate in a superimposed mannerMore +

-

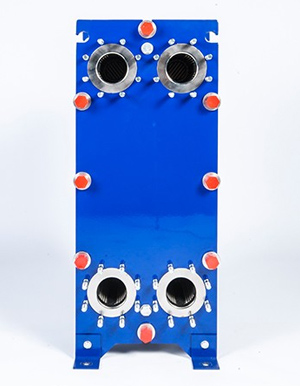

Plate heat exchanger

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that is assembled from a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between the various sheets, and heat is exchanged through the sheets.More +

-

Wide gap plate heat exchanger

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that is assembled from a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between the various sheets, and heat is exchanged through the sheets.More +

-

Food grade plate heat exchanger

A plate and frame heat exchanger as known as gasketed plate heat exchanger is a high efficiency heat exchanger that is assembled from a series of metal sheets with a certain corrugated shape. A thin rectangular channel is formed between the various sheets, and heat is exchanged through the sheets.More +

- [Medicine]Pharmaceutical industry2019.05.15 13:58

- Due to the ageing of the population, corresponding increase of chronic diseases and the preferential policies of the Chinese government, the scale of the Chinese pharmaceutical market has expanded rapidly, and factories have made considerable progress.

- read(80)

- [Metallurgy]Metallurgical Industry2019.05.15 13:54

- Metallurgy is the process of extracting metals or metal compounds from minerals and using various processing methods to make metals into metal materials with certain properties. Metallurgy has a long history of development, from the Stone Age to the large-scale development of modern steel smelting.

- read(57)

- [Electric power]Power plant2019.05.15 13:52

- In the 1970s, Europe entered the era of electric power revolution. As the demand for electricity increased, people began to propose the idea of establishing a power production center. With the development of motor manufacturing technology, the expansion of the application of electric energy, and the rapid growth of production demand for electricity, power plants have emerged.

- read(80)

- [Chemical]Petrochemical industry2019.05.15 13:48

- Currently, the general trend of the domestic and international petroleum refining industry is to develop into deep processing, comprehensive utilization, improving product quality, efficiency and reducing energy consumption. Therefore, the refinery equipment and heat exchange equipment are promoted to be large-sized, high-efficiency, flexible in operation, long-term operation, and conducive to the development of environmental protection and self-control.

- read(252)

- [Food]Food industry2019.05.15 13:42

- The food manufacturing process includes washing, cooking, concentration, sterilization, and moisturizing storage. And the process is mainly heating and cooling repeatedly. Water added during dilution, and heating is required for concentration. In order to prevent deterioration of quality during the storage and processing of raw materials, cooling is required.

- read(137)

- [Q & A]12024.05.10 15:23

- 1

- read(0)

- [Latest news]Heat station supporting plate heat exchanger installation is a technical work, these points should be noted2021.12.10 08:41

- Heat station supporting plate heat exchanger production completed need to be transported to the heat station for installation, many people will think that the installation is a very simple thing, in fact, it is not, the installation is also a technical work, there are also some matters needing attention, today to introduce exactly what places need to pay attention to.

- read(34)

- [Latest news]Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what2021.12.10 08:37

- With the continuous development of the sulfuric acid production industry, the demand for industrial plate heat exchangers used in the production process is also increasing, so do you know what issues should be noted in the design of heat exchange equipment for sulfuric acid?

- read(49)

- [Latest news]Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency2021.12.09 01:20

- Coal chemical plate heat exchanger in the use of a period of time, are more or less will produce some accumulation of scale, these accumulations will not only cause corrosion of the equipment, but also affect the efficiency of work, so to timely cleaning, today introduced a simple and limited chemical cleaning method.

- read(11)

- [Latest news]A high-quality petrochemical plate heat exchanger in the production of what to consider2021.12.09 01:12

- Petrochemical products are closely related to our lives, from space ships, airplanes, cars on the ground, to our daily use of computers, desks, clothing, a variety of building materials, etc., all have a close relationship with petrochemicals. The petrochemical industry provides us with all kinds of daily necessities.

- read(18)

- [Latest news]These causes of chemical plate heat exchanger gasket aging you may not know2021.12.08 07:39

- The chemical plate heat exchanger gasket is an extremely critical component, and the requirements for the gasket are extremely high in strong corrosive media. When we use, we will find that the gasket aging. What is the cause of this?

- read(12)

- [Latest news]Chemical plant plate heat exchanger, sulfuric acid cooling needs attention2021.12.08 07:37

- Sulfuric acid is produced with cooling, so chemical plant plate heat exchangers are used in many applications. In the sulfuric acid purification process, power wave scrubbers, cooling towers, fiber mist eliminators and heat exchangers for sulfuric acid cooling are used.

- read(34)

- [Latest news]High-end plate heat exchanger customization, specifically for your special working conditions2021.12.07 01:24

- With the expansion of plate heat exchanger application industries and fields, there are more and more special media and special working conditions, ordinary plate heat exchangers can no longer meet the requirements of use, the demand for high-end plate heat exchanger customization is growing, what are the conditions to meet its requirements?

- read(6)

Related search

Hot spot focusing

- 1Shandong Hengbang uses Ripute semi-welded evaporator and condenser case

- 2Haier new materials use Ripute small plate heat exchanger case

- 3Chuanqing Drilling Engineering Company uses Repute plate and shell heat exchanger case

- 4As a manufacturer of Plates and Gaskets, what are the advantages of Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd ?

- 5As a manufacturer of plate heat exchangers, what are the advantages of Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd?

- 6What are the advantages of plate heat exchangers compared to conventional heat exchangers?