As a manufacturer of plate heat exchangers, what are the advantages of Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd?

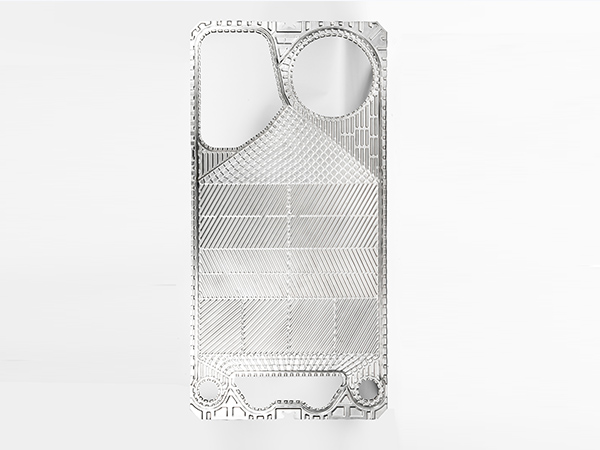

Adopting the same design software of Alfa Laval, GEA and other first-line brands to ensure the scientific, reasonable, optimized, high efficiency and stable performance of the heat exchanger design. The overall frame is made of high-quality raw materials that accord with international quality standards. Using large-scale precision equipment and production to produce. Our plate heat exchanger are with reasonable structure, exquisite craftsmanship, and beautiful appearance. It’s also with high heat exchange efficiency, high pressure bearing, corrosion resistance, compact structure, small footprint, stable operation and long service life.

We use NBR gasket with a temperature resistance of 140 °C even in general working conditions, which makes a wider scope of application and more stable operation. Laser welding and plasma welding technologies used in the production of semi-welded heat exchangers are far ahead than other factories in China, especially in the production of special materials such as titanium, titanium palladium and Hastelloy. We have rich experience and advanced technology in the design, manufacture and use of plate heat exchangers with special working conditions and special materials.

REAPTER is a professional manufacturer that recruits agents for global partners, wholesales of plates and gaskets, and wholesale heat exchangers. The quality is equivalent to the international first-line brand, the cost-effective choice, the market is broader.

Related information

- Haier new materials use Ripute small plate heat exchanger case

- All that you want to know about GEA NT Series plate heat exchanger is here

- Do you really understand the types and varieties of plate heat exchangers?

- After the plate heat exchanger is assembled, please read these before the normal operation of the production line!

- The heat exchanger has to be replaced after cleaning and removing the rubber gasket?

- Plate heat exchanger professional processing plant in which the main advantages?

Relevant article

- 1

- Can plate heat exchanger be directly used for feed water heating or cooling?

- Why the heat transfer efficiency of plate heat exchangers in the heating industry is low

- How to determine the size and angle of plate heat exchanger plate?

- What is the proportion of pressure drop in the selection of plate heat exchanger?

- Why do we recommend food grade plate heat exchanger for beer brewing and fermentation? What should we pay attention to?

- What is the difference between the hanging holes on the plate of plate heat exchanger?

- What are the applications of plate and shell heat exchanger in the field of petroleum refining

- What is the key to the manufacture of plate heat exchangers with small temperature differences?

- How to descale the plate heat exchanger? What problems should be paid attention to during use?

Latest information

- Heat station supporting plate heat exchanger installation is a technical work, these points should be noted

- Sulfuric acid and other corrosive media for industrial plate heat exchanger requirements are what

- Simple and effective chemical cleaning method of coal chemical plate heat exchanger, can effectively improve efficiency

- A high-quality petrochemical plate heat exchanger in the production of what to consider

- These causes of chemical plate heat exchanger gasket aging you may not know

- Chemical plant plate heat exchanger, sulfuric acid cooling needs attention

- High-end plate heat exchanger customization, specifically for your special working conditions

- The working principle of gasket type industrial plate heat exchanger and the scenarios of its use are worth knowing in depth

- Still worrying about the wholesale price of industrial plate heat exchangers? An article to make you no longer tangled

- The original lubricant in the chemical plate heat exchanger plays so many roles!