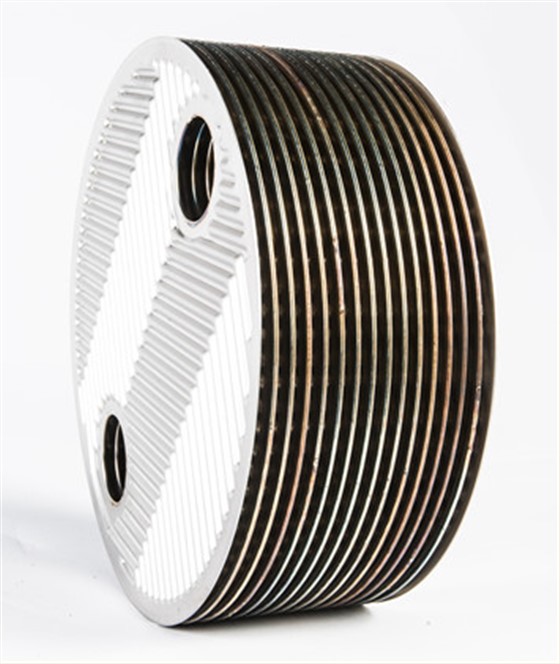

The round plate shell heat exchanger means that the internal plate bundle is welded with round plates, which is its main structural feature. This is followed by the shell of the pressure vessel, which is available in carbon steel, stainless steel and other materials. The use of welding eliminates the need for gaskets and increases the operating temperature and corrosion resistance.

Round plates are corrugated on the top, the medium forms turbulence on the surface of the plates, and the heat transfer efficiency is high. The use of round instead of square is due to the fact that round is easy to weld and has low stress. Qingdao Riput adopts the advanced technology of automatic plasma welding and applies it to the welding of the plates, which has large weld depth, good sealing performance and is not easy to leak.

This kind of round plate is made of various materials, mainly stainless steel 304, 316, 316L, etc. It has to be mentioned that the plate is made of stainless steel. It must be mentioned that there are other special materials, such as titanium, titanium palladium, Hastelloy C276, nickel, 904L, etc. Qingdao Ruiputeis experienced in welding of titanium, titanium palladium, Hastelloy C276, nickel, 904L, etc., which is of far-reaching significance for the use of severe conditions and complex media. Many customers also come to us because of our experience in manufacturing special materials.

The circular plate and shell heat exchanger is designed to achieve the optimum combination of plate arrangement by changing the angle of the plate corrugation, which can form flow channels of different efficiency and pressure drop, when combined into a heat exchanger. This best combination provides a rich variety of choice space, in the face of different conditions and the use of media, can find a specific combination of suitable.

Qingdao Ruiputehas been specializing in the research of heat exchanger technology for more than ten years, and at the same time, we have been continuously understanding the new requirements of the market for heat exchangers, and keeping pace with the times.

Food grade plate heat exchanger

Food grade plate heat exchanger Plate And Shell Heat Exchanger

Plate And Shell Heat Exchanger