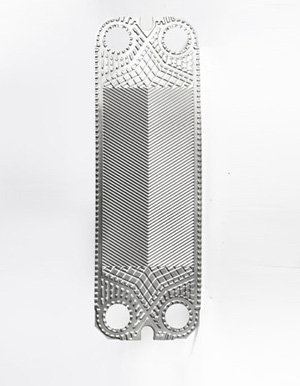

Plates for plate heat exchanger

- Alfa Laval Plates

- GEA Plates

- APV Plates

- Sondex Plates

- Tranter Plates

- VICARB Plates

- SIGMA Plates

- Funke Plates

- Thermowave Plates

- Plate And Shell Heat Exchanger Plate Pack

- Semi Welded Plate Heat Exchanger Plates & Gaskets

- Wide Gap Plate Heat Exchanger Plates & Gaskets

- Double Wall Plate Heat Exchanger Plates & Gaskets

- Special Material Plat Heat Exchanger Plate & Gasket

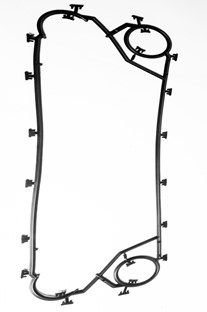

Gaskets for plate heat exchanger

Plate heat exchanger

Plate and shell heat exchanger

Double wall plate heat exchanger

Semi welded plate heat exchanger

Wide gap plate heat exchanger

Food grade plate heat exchanger

Semi welded plate evaporator

Semi welded plate condenser

mailto:info@reapter-phe.com

Location:No.1567,Wangsha Road,Xifuzhen Sub-district, Chengyang District,Qingdao City, China.

Gaskets For Gasketed Plate Heat Exchanger

1.The synthetic rubber raw materials and auxiliary materials are purchased from international first-line brands such as German LANXESS to ensure excellent product quality, good stability, high quality of finished products and long service life.

2.We have our own R&D laboratory with advanced testing equipment and testing methods, all in accordance with international standards, testing raw materials and heat exchange media, and formulating different solutions for different media.

3.The physical properties and pressure change properties of the rubber gaskets are in line with international standards. Among them, the temperature of NBR reaches 140 degrees, which solves the technical difficulties of EPDM suitable in good temperature resistance but not oil, which makes heat exchangers are more suitable with a wider range and better performance.

4. We have a full range of imported plate heat exchanger gasket molds, such as Alfa Laval, GEA, Tranter, Sondex, APV, Vicarb, and Funke, and has the ability to develop high-precision molds. The shape, thickness, hardness and other physical indicators of the rubber gaskets meet the same standards as the international first-line brand Gislaved gummi.

5. Mainly adopt the production process standard and quality management system common to international first-line brands. The performance of the rubber gasket is superior, the compression deformation rate is 10% less than the national standard, the sealing performance is good, the service life is long, the pressure is high, and it is more resistant to complex media.

6. In special rubber types such as fluorine (Viton/FKM) rubber gaskets and neoprene, we have advantages in production technology, and many years of experience in cooperating with foreign customers, advanced technology, and the products have passed the US FDA food-grade certification.

Gaskets material: NBR, EPDM, HNBR, CR, VITON/FKM, FDA sanitary

Hanging method: Glued, Hang on, Clip on, Snap in, Paraclip, Sonderlock.

*Other materials may be available on request.

Consulting

Consulting