-

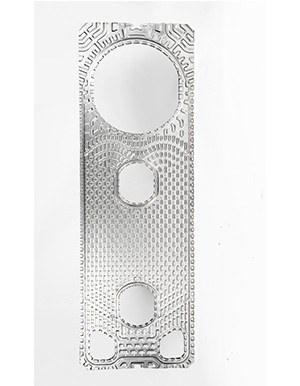

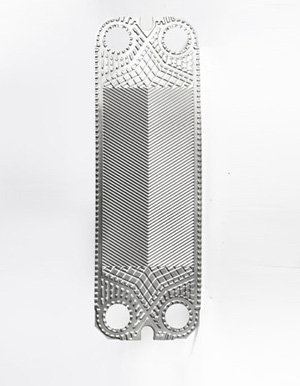

Double Wall Plates And Gaskets

The plate of the double wall plate heat exchanger replaces the single plate type with two welded plates. Once the plate is cracked or perforated, the fluid will flow between the two plates to the outside, which is easy to be found and taken. Doing this can avoid contamination or adverse reactions caused by the mixing of the two heat exchange media.More +

-

Semi Welded Plates And Gaskets

All sealed edges of the two corrugated sheets are laser welded into "sheet pairs" to form welded channels; each pair of sheets is gasketed to form a detachable regular flow path. This structure allows easy maintenance of each pair of plates while ensuring the stability of the welded plate pairs.More +

-

Thermowave Plates

Special corrugated plates can provide more than one channel combination of regular heat exchanger plates. According to different working conditions, design and flow channel layout can be provided. More matching models can be selected to achieve flow conditions. It can meet the optimal match of economy and heat transfer performance.More +

-

Thermowave Gaskets

Special corrugated plates can provide more than one channel combination of regular heat exchanger plates. According to different working conditions, design and flow channel layout can be provided. More matching models can be selected to achieve flow conditions. It can meet the optimal match of economy and heat transfer performance.More +

-

Funke Plates

Unique “Off-set” plate design, which can be combined into symmetrical or asymmetric flow channels to provide a more economical and reasonable heat exchanger.More +

-

Funke Gaskets

Unique “Off-set” plate design, which can be combined into symmetrical or asymmetric flow channels to provide a more economical and reasonable heat exchanger.More +

-

Vicarb Plates

Each plate has a different corrugation angle, which can be combined with different flow paths to achieve the best match between heat transfer performance, pressure drop and economical efficiency.More +

-

Vicarb Gaskets

Each plate has a different corrugation angle, which can be combined with different flow paths to achieve the best match between heat transfer performance, pressure drop and economical efficiency.More +

-

Tranter Plates

Each plate has a different corrugation angle, which can be combined with different flow paths to achieve the best match between heat transfer performance, pressure drop and economical efficiency.More +

-

Tranter Gaskets

Each plate has a different corrugation angle, which can be combined with different flow paths to achieve the best match between heat transfer performance, pressure drop and economical efficiency.More +

-

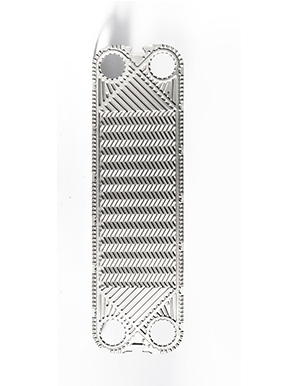

Sondex Plates

Using ultra-fine mesh numerical simulation technology combined with precise experimental measurement methods to make the plate flow and heat transfer performance superior.More +

-

Sondex Gaskets

Using ultra-fine mesh numerical simulation technology combined with precise experimental measurement methods to make the plate flow and heat transfer performance superior.More +

-

APV Plates

Advanced high-efficiency split-flow guide area plate design, uniform medium flow rate and high heat transfer coefficient.More +

-

APV Gaskets

Advanced high-efficiency split-flow guide area plate design, uniform medium flow rate and high heat transfer coefficient.More +

-

GEA Plates

We have full specification on plate type and size, with specific thermal performance and pressure drop, which can meet the requirements of various media and working conditions.More +

-

Alfa Laval Plates

Unique split-flow design, even flow rate, removes the dead zone of flow velocity, avoids corrosion caused by dirt accumulation, and improves the utilization rate of heat exchange area of the plate.More +

-

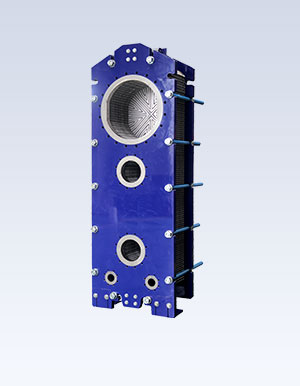

Plate And Shell Heat Exchanger Plate Pack

A bunch of circular plates made of stainless steel or other alloy material are laser welded into one body, called a heat exchanger lathed bundle, then placed in a cylinder to form a plate and shell heat exchanger. The plate and shell heat exchanger has the advantages of temperature resistance and pressure resistance with shell and tube heat exchanger, and also the advantages of high efficiency, compactness with plate heat exchanger.More +

-

Plate And Shell Heat Exchanger

The plate and shell heat exchanger adopts a circular corrugated heat exchanger plate that welded into a heat exchanger lathed bundle and combined with the structure of the pressure vessel shell. It also has a high heat transfer efficiency,compact structure and resistant to high temperature & pressure like shell tube heat exchanger. The plate and shell heat is durable under high temperature & pressure,large temperature difference and thermal shock, which is in a leading position in the industry.More +

-

Double wall plate heat exchanger principle

The double wall plate heat exchanger plate is welded integrally with two thin plate pieces along the corner hole of each pair of plates. When the plate leaks, for example, the perforation caused by long time working will be easily detected from outside. Thereby it stops mixing between two materials.And at the same time, they plays very important roles towards warning internal leakage. Combined with the double seal of the gasket, the possibility of mixing two materials is avoided, and it is suitable for applications with high sanitary requirements or high safety and reliability of industrial production. Since the two sheets are welded to form a sheet, the heat transfer coefficient is inevitably lowered, but the highest safety is achieved in preventing materials mixing.More +

-

Semi welded plate condenser

The plate condenser consists of plates that are welded together in pairs to form a so-called plate set. The concept of a plate set leads to two different types of channels: a weld channel for condensing steam and a gasket seal channel for cooling water. This type of plate is specially designed for optimum condensation. It has an asymmetrical arrangement with a large gap on the steam side and a small gap on the cooling water side. This makes it possible to maintain a very low pressure drop at the steam end while maintaining a certain speed and turbulence on the cooling water side. This maximizes heat transfer efficiency and minimizes fouling.More +

Related search

Hot spot focusing

- 1Shandong Hengbang uses Ripute semi-welded evaporator and condenser case

- 2Haier new materials use Ripute small plate heat exchanger case

- 3Chuanqing Drilling Engineering Company uses Repute plate and shell heat exchanger case

- 4As a manufacturer of Plates and Gaskets, what are the advantages of Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd ?

- 5As a manufacturer of plate heat exchangers, what are the advantages of Qingdao Ruipute Heat Exchange Equipment Manufacturing Co., Ltd?

- 6What are the advantages of plate heat exchangers compared to conventional heat exchangers?